TurboRotary13b

Crossed Swords Squire

- Joined

- Dec 27, 2012

- Posts

- 187

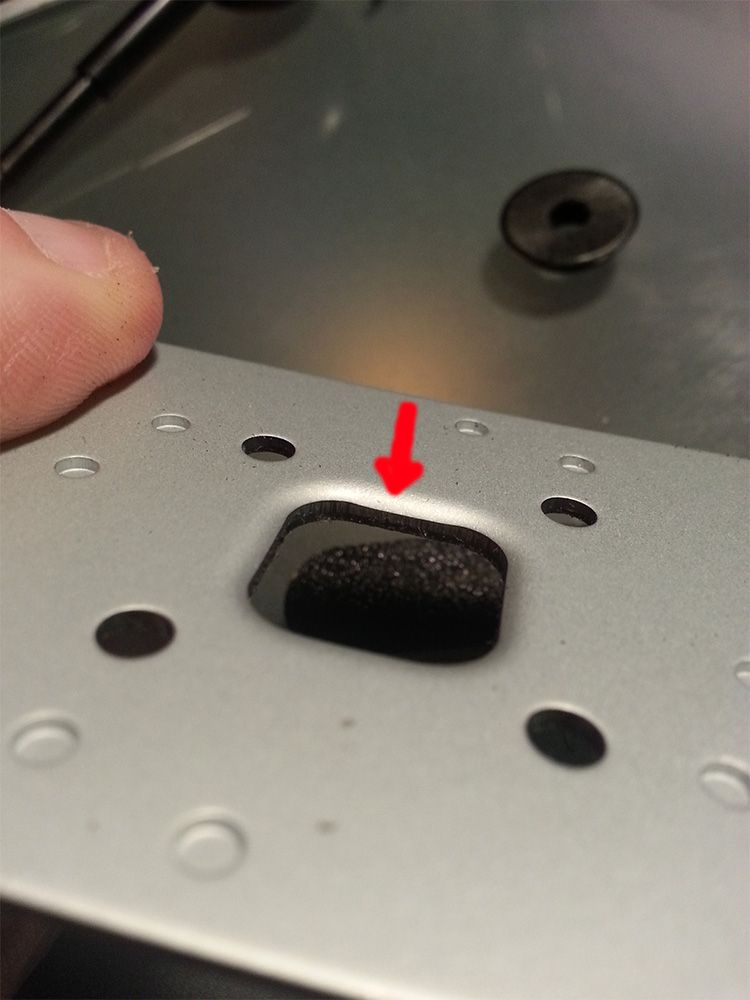

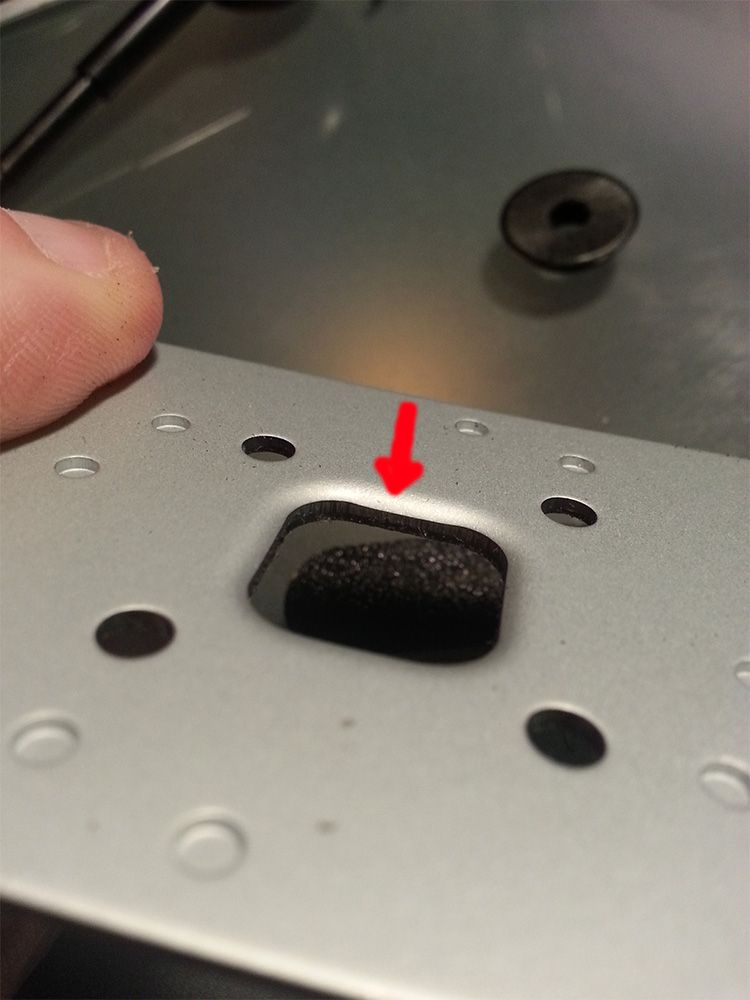

I have an extra stick I use for MAME so I decided to play around a little and try to figure out what exactly was causing the stick bump. Part of the problem lies here..

The very end of the stick falls down into the beveled edge causing the bump feeling.

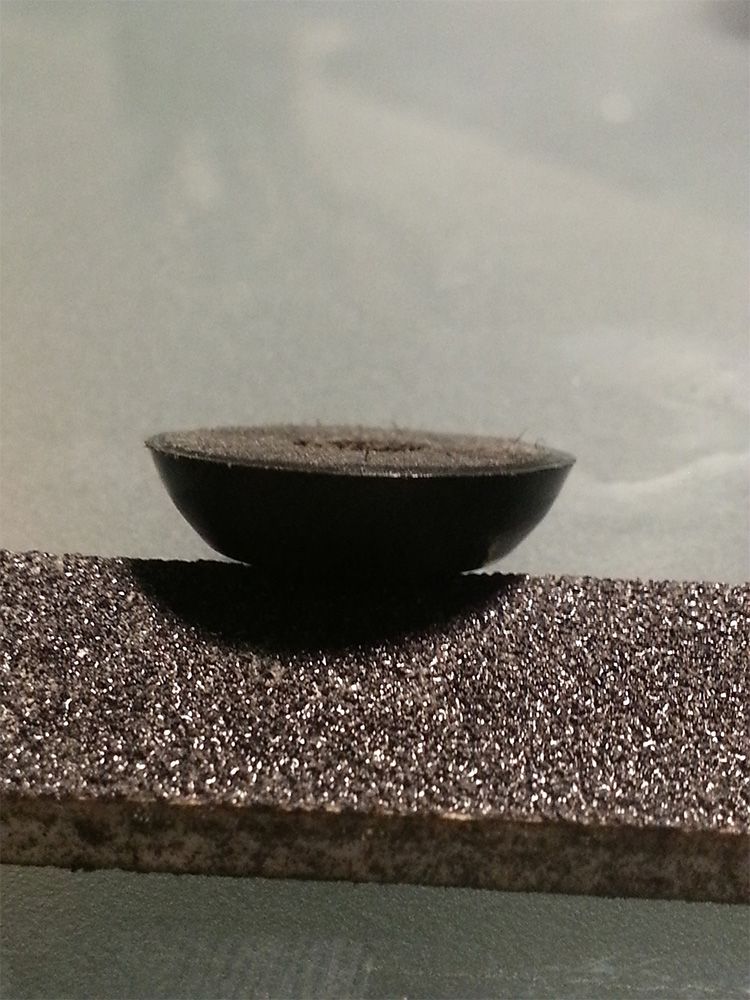

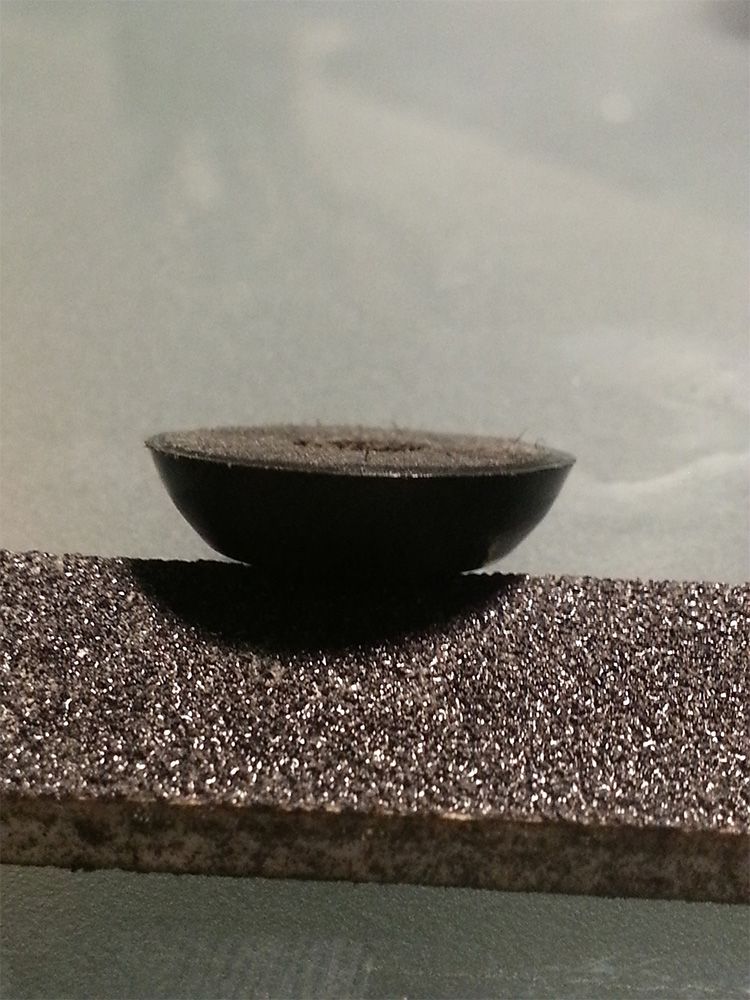

Cutting or filing down the part shown below allows for the stick to sit further down in the guide hole and helps to prevent it from moving downward into it. You want to alter the part that sits on the shell.. Not the more rounded side, of course.

This part is found under the actuators between the top plastic shell and the bracket that the actuators are attached to. You have to remove the C ring that hold the spring to the stick to get to this. Once its done you can pop it back together and not have to worry about this annoying issue anymore. This is a quick method with no need for any extra parts!

The very end of the stick falls down into the beveled edge causing the bump feeling.

Cutting or filing down the part shown below allows for the stick to sit further down in the guide hole and helps to prevent it from moving downward into it. You want to alter the part that sits on the shell.. Not the more rounded side, of course.

This part is found under the actuators between the top plastic shell and the bracket that the actuators are attached to. You have to remove the C ring that hold the spring to the stick to get to this. Once its done you can pop it back together and not have to worry about this annoying issue anymore. This is a quick method with no need for any extra parts!

Last edited: